Four Methods of Dewatering and How to Choose One

In many construction works, such as building foundations and basements, you will have to deal with groundwater and surface water management. They should be controlled to ensure easy and safe accomplishment of the work on the construction site.

That’s when dewatering comes into play.

Dewatering, as its name suggests, is the process of removing surface and subsurface water from a construction site.

Whether you have to remove small amounts of water in case of shallow excavations (up to 1.5 m deep) or have to control large quantities of water in deep excavations (over 3 m deep), you will need to consider a wide range of methods to make sure adequate precautions have been taken.

Why Dewater?

Dewatering provides dry and stable conditions for excavations, allows to increase the stability of the soil, and ensures workers’ safety.

If for some reason surface and sub-surface waters are not properly collected and disposed of, they can pose significant hazards during construction site preparation and, later on, during the building’s life cycle.

Image source: HSI Services, Inc

Image source: HSI Services, Inc

The damage may be of different types:

- The conditions of the soil may undergo variations that can affect the structure of the building.

- It may become a reason for surface flooding.

- If you don’t pay proper attention to the place where water is discharged, you may run the risk of witnessing erosion and other related problems.

- Dampness may lead to unhealthy conditions and attract termites.

- Flooding may damage adjacent properties.

Builders, designers and other specialists involved in the construction process should make sure the site preparation is done professionally so that groundwater is removed as required and surface water always runs away without the risk of being banked up.

What To Consider Before Choosing A Dewatering Method?

You should base your decision on a number of information sources.

Refer to the geotechnical and groundwater site investigations and risk assessments accomplished in the scope of your construction project and, if needed, consult with the information provided by local authorities.

In most cases, you will need specialist engineering services to take care of soil stabilisation and successful control of groundwater.

The common process of dewatering involves the following phases: collection of water, pumping, filtering/removing silt, and discharge.

Image source: SlideShare

Image source: SlideShare

Methods Of Dewatering

We have singled out four commonly used methods: sump pumping, wellpoints, deep wells, and eductor wells. These techniques can be employed singularly or in combination depending on the nature of the soil and groundwater conditions.

1. Dewatering By Open Sump Pumping.

It’s a reliable choice in a wide range of situations, and it’s also referred to as the simplest, cheapest, and most effective dewatering method.

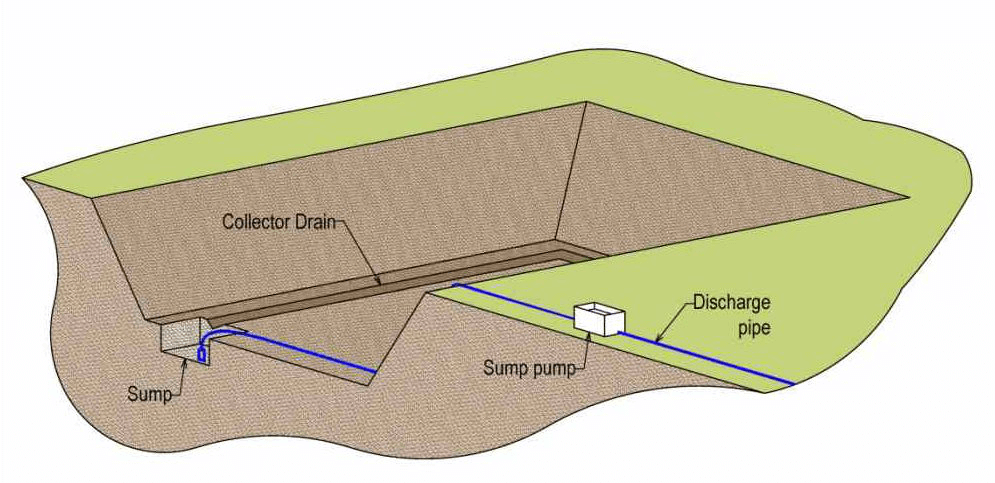

A sump is a hole or an area in the ground (deeper than the basement floor) where water is collected and then pumped away for disposal.

How it works.

Drains and sumps are constructed at one or more sides or corners of the foundation pit. The drains collect the groundwater and convey it into the sump. From the sump, the water is continuously evacuated (either manually or mechanically).

Image source: Gharpedia

Image source: Gharpedia

This method works well for most soil and rock conditions (can be applied in well-graded coarse soils or in hard fissured rock).

Consider scenarios when you should be cautious. When using this technique, there is a risk of collapse of the sides as “the groundwater flows towards the excavation with a high head or a steep slope”. In fine-grained soils, such as silts and fine sands, there is also a risk of instability which may result in ground movements and settlement.

2. Dewatering By A Well Point System.

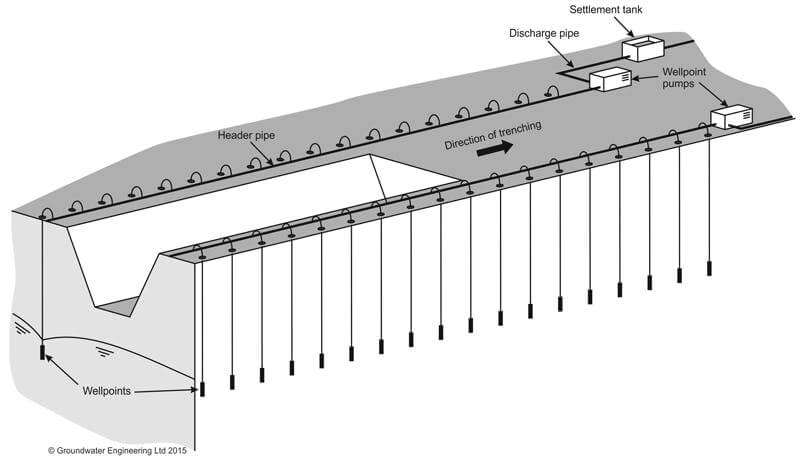

This method features easy installation, and it’s relatively cheap and flexible, being practical and effective under most soil and hydrologic conditions. Wells are drilled around the construction area and pumps are placed into these wells.

Image source: Gharpedia

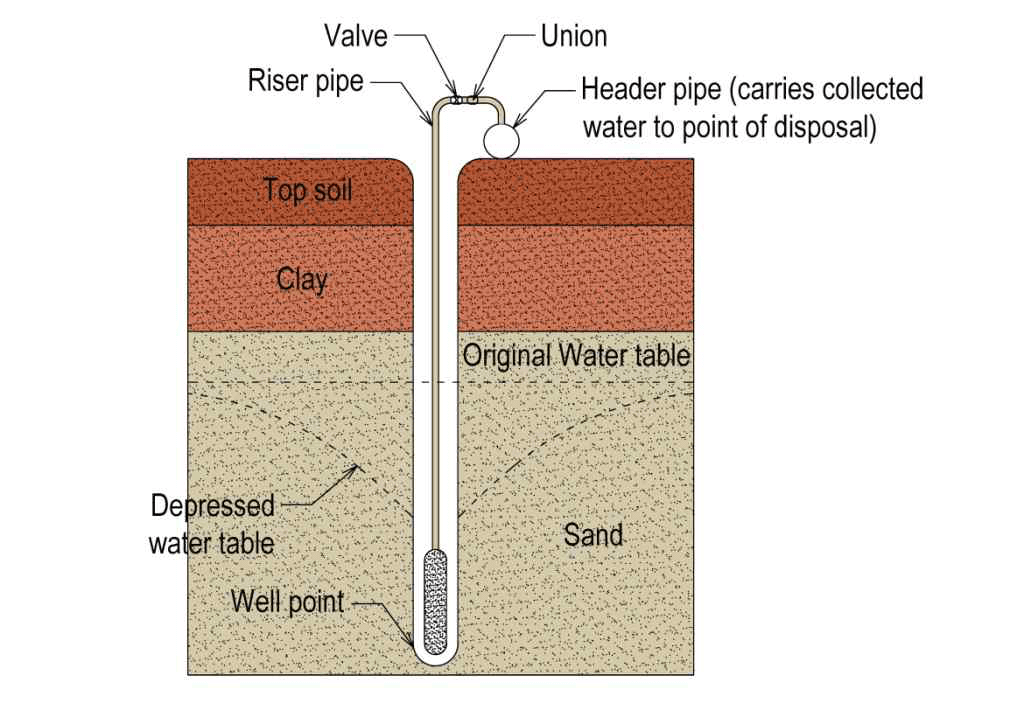

Wellpoint systems consist of a series of small-diameter wells, connected by a header pipe to a centrally located suction pump. Groundwater is abstracted via the wellpoints from a vacuum generated by the pump.

The perforated pipe has a ball valve to regulate the flow of water (the ball valve also prevents the mud from entering into the pipe). Groundwater can be lowered about six metres by this method.

Image source: Groundwater Engineering

Image source: Groundwater Engineering

This method is ideal for buildings with deep basements and is effective in sands and sandy gravels.

Image source: GEOQUIP

Image source: GEOQUIP

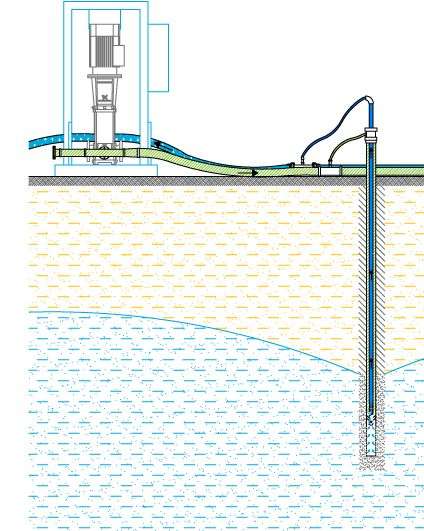

3. Dewatering By Constructing Deep Wells.

When a deep excavation is needed and a large quantity of groundwater is required to be removed, dewatering may be done by constructing deep wells in soils or rocks where permeability is between moderate (e.g. sands) to high (e.g. gravels).

Image source: The Constructor

Image source: The Constructor

Deep well dewatering system can drain out water up to 24m depth. The capacity of the pumps as well as the number, depth, and spacing of deep wells may vary depending on the site conditions.

In cases when wellpoints and deep wells are not suitable methods for dewatering, the use of eductors can be considered.

4. Dewatering Using The Eductor System

The eductor system (also known as the ejector system) is a specialist technique used in low permeability soils such as very silty sands, silts, or clays. Eductors are typically used to help stabilise the side slopes and soil in the excavation area.

Unlike the wellpoint dewatering system, it uses high-pressure water in the riser units. The eductor system works in the following way: “Ejector supply pumps located at ground level feed high-pressure water to the ejector nozzle and venturi located at the base of the wells. The flow of water through the nozzle generates a vacuum in the well and draws in groundwater”.

Image source: WJ Middle East

Image source: WJ Middle East

Wrapping Up!

To survive and thrive in an environment where more and more buildings are designed and built, construction specialists have to be knowledgeable in the industry laws and regulations and competent to accomplish construction projects – from demolition to excavation, from glazing to maintenance.

More than ever before, Australia needs highly skilled professionals to meet the ever-increasing workforce demand in the construction industry.

That’s when the need for a recognized training provider arises.

Back to Basics is here to help you receive high–quality training at an affordable price and in the shortest time frame possible.

Sounds promising? That’s only the beginning.

- You enjoy the flexibility and efficiency of learning online.

- You gain access to training materials written by builders for builders.

- You receive one-on-one training from industry experts.

If you would like more information on the courses Back to Basics offers or are interested in upgrading your resume with one of our qualifications, Call us on 1300 855 713 or email enquiries@backtobasics.edu.au to find out more.